Industrial Friction Materials - Research & Development

Our priorities as a manufacturer are safety and quality.

Rigorous testing, continuous upgrade of in-house technology and support from strategic development partners have enabled World Brake to enhance technical competencies at all levels.

To achieve effective control on quality production, our production facility includes an in-house quality control department. This integrated department consists of all types of requisite test equipment including compression tester, hardness tester, chase machine, and U.T.M machine to ensure that the product meets company standards. Testing is carried out by our experienced quality control inspectors who inspect the finished products in order to ensure defect-free products.

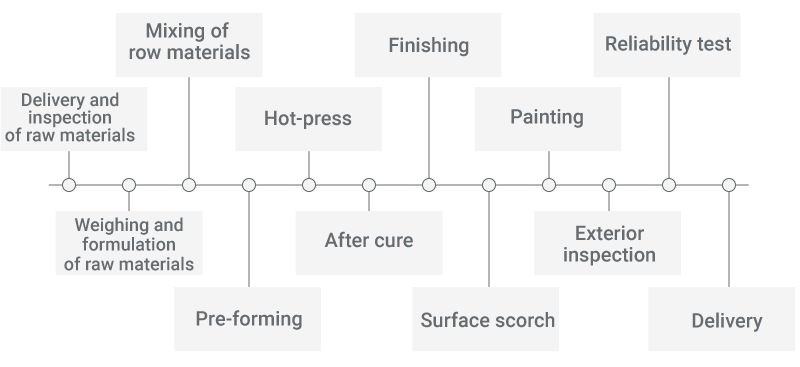

Apart from lab testing, our products are checked at three different areas in our production line.

- Raw material testing

- On-line inspection

- Final inspection

In the inspection stage, quality control parameters and standard inspection ensure that the final product is engineered to precision. We focus on final end result, increasing the productivity and enhance quality with cost effective by practicing kaizen.

We are dedicated to the Total Quality Management approach that measures and monitors our products and processes to ensure consistent results and continuous improvements.

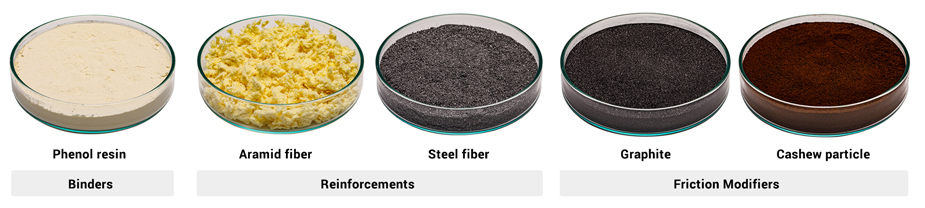

Raw Materials

One of the stars of any friction material is phenolic resin. Used as a binding agent, this raw material is cured through a high-heat, thermoset reaction. As a result, linings that have higher amounts of phenolic resin maintain strength and integrity over time. Phenolic resin also helps improve lining wear/life at low temperatures, making it key for over-the-highway applications. Two other vital raw materials are chopped fiberglass strand and abrasives (aluminum oxide). Fiberglass increases the flexural strength of a friction material, effectively minimizing cracking because of its ability to reinforce and strengthen. Abrasives like aluminum oxide are the raw materials responsible for creating the torque when brake linings are used during a stop – quite literally, the friction.

Graphite is also an important raw material, as it is temperature resistant and acts as a lubricant for the lining, thus greatly aiding in reducing wear and stabilizing friction level. Because different types of graphite exhibit varied frictional characteristics, many combinations or forms of graphite may be used in a friction formula based on the application of the lining.

Rubber and friction particle, along with graphite, are part of a second tier of raw materials from an importance/cost perspective. Rubber, typically recycled tire treads, and friction particle derived from cashew shells are both organic materials that help to make the friction softer and more compressible.

Other inorganic minerals such as calcium carbonate, barytes, and wollastonite, commonly referred to as fillers, are mined directly from the earth and as a result are generally inexpensive. But because these ingredients are naturally sourced, they require purification processes before being considered acceptable for a friction material. However, it can be costly to set up and maintain high quality separation and purity processes.

Excellent Performance and Durability

To ensure the quality and high performance of its friction materials, Fras-le invests heavily in precision processes.

- High performance and durability

- Excellent wear resistance

- Resistance to severe temperature conditions

- Low aggressiveness to the drum Safe Braking

- Excellent Compatibility with the brake drum